| Stud & Track Systems Home |

H.D. Stud & Track System | E-Stud Line System |

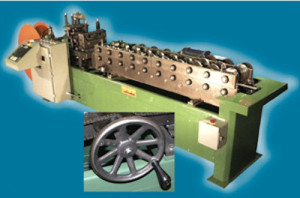

The E-Stud Line is compact and designed for the light commercial industry. Its construction allows it to be taken to the job site, relocated within the plant where needed. It can also be easily stored between jobs or applications. This is not a light duty, chain drive, portable, job site throw away. The E-Stud eliminates extensive coil changeovers and roll spacer tooling setups. Once you understand all the features the E-Stud provides, nothing else will compare in price for years of dependable service. The E-Stud Line is compact and designed for the light commercial industry. Its construction allows it to be taken to the job site, relocated within the plant where needed. It can also be easily stored between jobs or applications. This is not a light duty, chain drive, portable, job site throw away. The E-Stud eliminates extensive coil changeovers and roll spacer tooling setups. Once you understand all the features the E-Stud provides, nothing else will compare in price for years of dependable service. |

See Video – Click Here

Economical Programmable

The E-Stud Line is an economical alternative to eliminate all the extensive setups and changeovers and to maximize your overall Stud and Track production. Eliminating the coil changeover from Stud to Track is a real time saver and allows you to run and/or bundle everything needed for a wall or section on a just in time basis. |

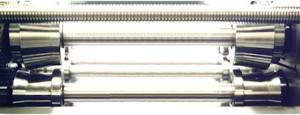

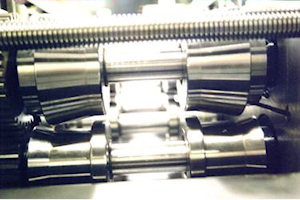

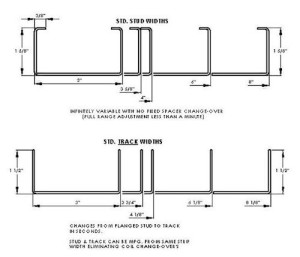

Variable Width RollformThe main feature that really makes this system great is our Variable Head Rollformer. It positions the Roll Tooling with a simple Lead Screw Handwheel. The Variable Tooling is the same concept used on all our heavy-duty industrial Stud and Track, and Joist Rollformers. We are the only company that offers this feature on a Stud and Track System in this price range.

|

Click Here for Flyer

The E-Stud uses a Programmable Pre-Punch, Pre-Cut System along with a Variable Head Rollformer. These features are usually only on heavier Industrial Stud, Track and Girt Lines. The Programmable Pre-Cut System produces a better cutoff end condition. It also eliminates die changes between Stud sizes and Stud to Track changeovers. The Variable Head Rollformer is designed to position and vary the Rolls using a simple Lead Screw setting in less than a minute. This gives you an infinite variation from the widest to narrowest Stud and Track size range. This eliminates a time consuming spacer setup and limited size selection. Tracks can be sized to fit the Studs throughout the full gauge range for a snug tight fit. |