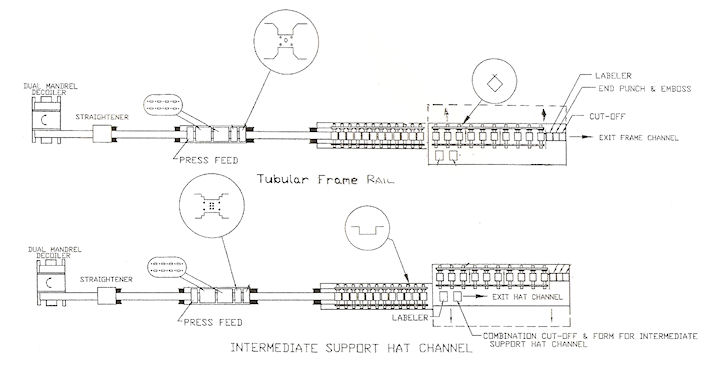

This line was designed and made by Custom Rollform Products for a manufacturer of Air Make-Up Units. The main body or structural enclosures of these Units consist of two basic components, the Frame Rails, and the Intermediate Supports.

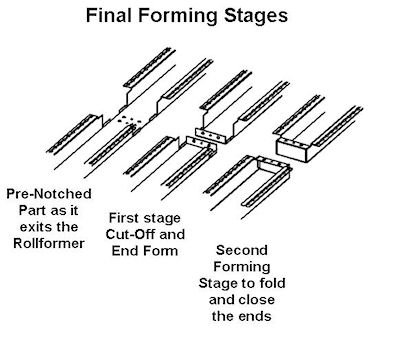

| Both the Frame Rail and the Intermediate Support are made from 16 gauge pre-painted or galvanized mild steel. They are made from the same 9.625″ coil slit width. The Intermediate Support for the Air Make-Up Units is primarily a 4” wide Hat Channel Profile. It has 2” vertical flanges and 1” opposed horizontal edge flanges on both sides.The Support Hat Channels need to be continuously punched down on both edge flanges. They are pre-notched and endformed on both the lead and trail ends. We made a special Combination Cutoff and Endform Press. The Press forms and folds both ends of the part inline as the parts are being cut to length. |  |

|

|

The Tubular Frame Rails were also made on the same Coil Feed Rollform System. They were made from the same 16 gauge coil stock and slit width used for the Hat Channel Profiles. Feeding the 4” Hat Channel Profile through additional Rollform Tooling and Stations produces the 2” square Tubular Frame Rails. Using Pre-Tooled Pre-Notch and Punch Dies, a quick change Rollform Tooling setup, and two special Pre-Tooled Cutoff and Endform Presses, both products are produced on the same Coil Fed System with a minimum amount of setup, downtime, or scrap loss.

Automatic changeovers from Tubular Frame Rail to Intermediate Support make this a true just in time production system. This will improve your lean manufacturing capabilities. |

|

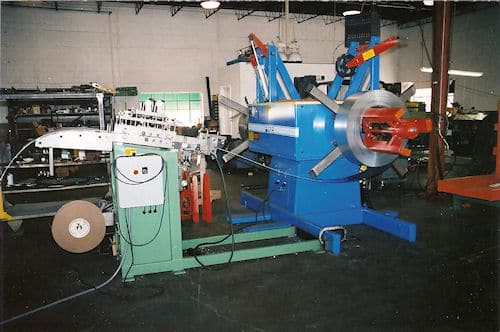

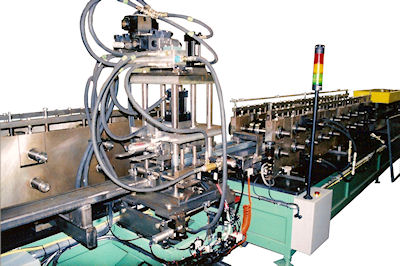

| The complete Coil Fed, Punch, Notch, Rollform, and Endform System consist of a Dual Mandrel Decoiler, Powered Feeder Straightener with Sonic Loop Control, a series of Pre-Tooled Hydraulic Punch / Notch Dies with a Programmable Rollfeed, a special Pre-Tooled Twenty Four Station Rollformer, and two complete sets of Cutoff and Endform Presses.

The Dual Mandrel Decoiler is designed for a quick changeover from pre-painted to galvanized stock. You could also pre-load for the next coil to be run. The one set of Coil Mandrels can be changed over offline as the other set is feeding the coil strip into the System. The Air Make-Up Units Hydraulic Punching and Notching System consist of six Pre-Tooled Inline Press Dies. Two Presses are designed to continuously punch a combination slot / hole punch pattern down both edges of the coil strip in 12” increments. Two other Presses are pre-tooled and inline to pre-punch and notch the lead and trail ends of the parts for either the Frame Rails or Intermediate Support sections. The other two Press Die Units punch holes down the length of the Tubular Frame Rails as required. |

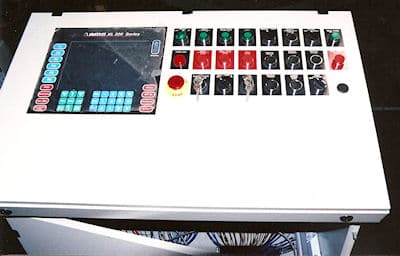

The programmable Rollfeed sequences the Coil Strip Feed and cycles the Presses through the AMS Microprocess Length Batch Controller. Parts can be Keyboard entered or directly downloaded from an in-office AutoCAD DXF file with the Eclipse option. |

|

View of the Pre-Notch and Punch System. Edge slots and holes were progressively punched on 12″ increments. Lead and trail End Notching and Punching Press / Dies are pre-tooled inline for the Tubular Frame and Intermediate Support Profiles. Part lengths and quantities are downloaded directly from an interoffice AutoCAD drawing of the individual Air Make-Up Housings required.

The Rollform Feed will sequence and feed the strip, and form the Frame Rail Profile. It then feeds it directly into the pre-tooled two stage, Punch Emboss and Cutoff Presses. The two Dies are designed to sense and pilot into the rollformed pre-notch. They then punch and emboss the lead and trail ends then into a Combination Punch, Emboss and Cutoff Press Die. Cutting, punching, and forming the lead and trail ends automatically and inline eliminates any secondary offline operations. The design of this Framing System is very unique. Special interlocking tab ends on the Frame Rail produce a strong interlocking corner without any secondary parts or fixtures. The extruded holes and counter sinks formed in the Cutoff Die allow the parts to be directly fastened with self-threading screws. The fact that both parts are produced from the coil strip simplified the part changeover and flexibility of the System. |

The manufacturer designs each Air Make-Up System. They direct download all the sizes and specifications directly into the Microprocess Length Batch Controller. As the parts are produced, the System produces a corresponding label to identify the part, usage, and location in the assembly.  The pre-punched and notched coil strip will feed directly into the first stage Pre-Tooled Fourteen Station Rollformer. It is designed to make the Intermediate Support Hat Channel Profile. As the formed part exits the Rollformer it will feed directly into a specially designed Hydraulic Cutoff and Endform Press Die. The Die for the Air Make-Up Units will sense and pilot off the rollformed, pre-notched opening. The Die is designed to fold, form, and swedge leading and trailing ends of the Intermediate Support Hat Channel Profile. This is done as it cuts the parts to length. Using a programmed cutoff and forming cycle, the Die will double fold a return flange on both ends. It does this as it swedges the two side edge flanges together to produce a completed part automatically and inline. Using the programmed multistage form cycle, Hydraulic Cylinders are mounted above, below, and on both sides of the Cutoff and Form Press. All the forming operations are hydraulically sequenced and cycled. This eliminates any mechanical cams or slides within the Die. This combination Cutoff and Form Press eliminates a series of downstream or additional offline operations to complete this part. One of the most unique features of the Air Make-Up Units System is the ability to automatically changeover from the Intermediate Support Profile to the Tubular Frame Rail in approximately two minutes, with a minimum amount of downtime, setup, or scrap loss. After the Punch Notch System has run all the Hat Channel Profiles, the program changes the pre-notch within the coil strip and continues to punch and notch the strip for the Tubular Frame Rails. The new pre-notch feeds out of the Punch Presses, through the slack loop, and into the Rollformer. There is a Pinch Rollfeed and Cutoff Press mounted directly in front of the Rollformer with Sensors to read the pre-notch. When it reads a different pre-notch the Rolls clamp and hold the strip as the Shear Die cuts the strip. The strip will continue through the Rollformer post cutting and endforming the remaining parts. Once all the parts are cleared from the Rollformer and Cutoff, the last ten Stations of the Rollformer will laterally shift inline with the first fourteen Stations Rollformer. This makes for a total of twenty four stations to produce the tubular Frame Rail. At the same time the Intermediate Support Cutoff and Form Die is shuttled offline. |

|

|

The overall accuracy of all the punching and notch is very critical to insure alignment of the parts and panels together. This System has been in service since 2003 producing parts for two of their manufacturing plants on a daily production schedule. Everything you see on this line was designed, built, and made by Custom Rollform Products.

All our Systems are engineered, wired, plumbed, and programmed to insure we can service everything we sell. Buying a System built by a single source manufacturer will guarantee you quick service and years of quality production. Let Custom Rollform Products show you what you can do to increase your productions minimize your labor and scrap loss, and improve your bottom line. |

|

|

||

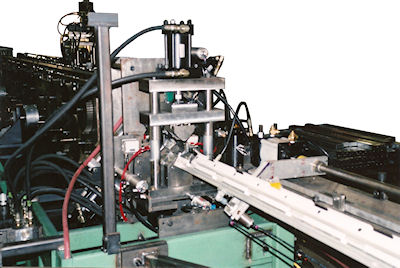

The Cutoff Die for the Intermediate Support Hat Channel Section was a Multi-Stage Hydraulically Activated System. It was designed to pilot and cutoff the pre-rollformed sections at the Pre-Notch as it forms the ends in one cycle. This eliminated second tangent forming operation and setups for various part lengths.

The Cutoff Die for the Intermediate Support Hat Channel Section was a Multi-Stage Hydraulically Activated System. It was designed to pilot and cutoff the pre-rollformed sections at the Pre-Notch as it forms the ends in one cycle. This eliminated second tangent forming operation and setups for various part lengths. To produce the 2″ square tubular frame rail from the 4″ Hat Channel Profile, the Channel Web needs to be narrowed approximately 1/8″ to compensate for the bend allowance. The coil strip is then cleared from the first Rollformer, the Roll Tooling is automatically re-positioned using Hydraulic Cylinders on Rollform Stations five through fourteen. With all twenty four Rollform Stations inline, Roll Tooling, and properly indexed, the System will feed the coil strip through the complete set of Rollform Stations to manufacture the Tubular Frame Rails.

To produce the 2″ square tubular frame rail from the 4″ Hat Channel Profile, the Channel Web needs to be narrowed approximately 1/8″ to compensate for the bend allowance. The coil strip is then cleared from the first Rollformer, the Roll Tooling is automatically re-positioned using Hydraulic Cylinders on Rollform Stations five through fourteen. With all twenty four Rollform Stations inline, Roll Tooling, and properly indexed, the System will feed the coil strip through the complete set of Rollform Stations to manufacture the Tubular Frame Rails.