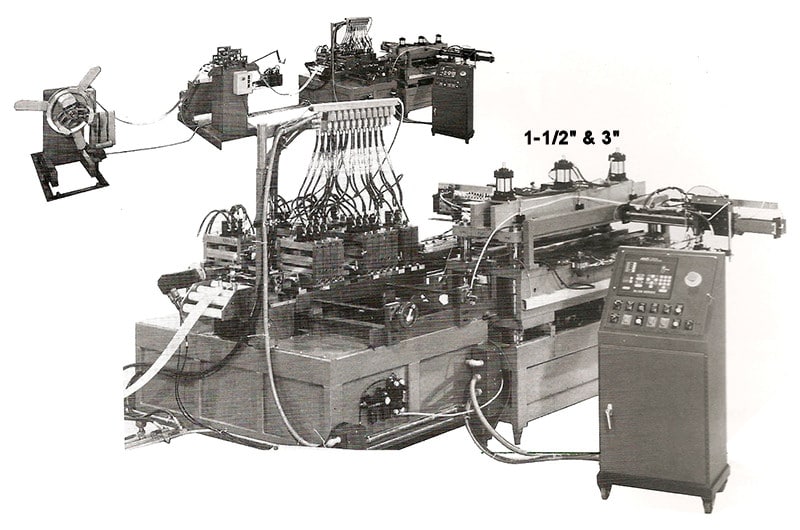

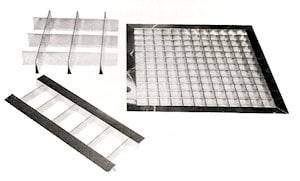

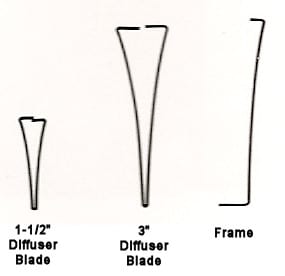

This Light Diffuser System produces the Linear and Lateral Diffuser Blades and Outer Frame Sections for 1-½” and 3” deep.

|

Utilizing a Servo Feed and High-Speed Hydraulic Presses, the Light Diffuser System pre-notches the sections. It does this for the interlocking notches and tabs using a combination of gang and gag sequences. The pre-cut and notched parts are then fed directly into a specially designed Hydraulic Forming Press. The Press positions the parts within the Die. It then forms the part in a two stage sequence. Then it ejects the part from the opposite side. The Controller allows the Operator the choice of pre-positioning or spacing the Individual Notch Dies. They can run a high-volume gang punch and gagged sequenced production. They could also run lower-volume parts can be run in a variety of cell configurations using the Index Feed (no setup required).The Notch, Punch, and Tab Presses are mounted on two separate Die Beds which allows the Operator to setup for the next run while running product on the other setup. The Form Press also includes hydraulic clamping and built in stops to minimize downtime for changeovers and setups. All Diffuser lengths and patterns can be setup in minutes and complete changeovers from the 1-½” to 3” Diffusers can be completed in 15 to 20 minutes. |