|

|

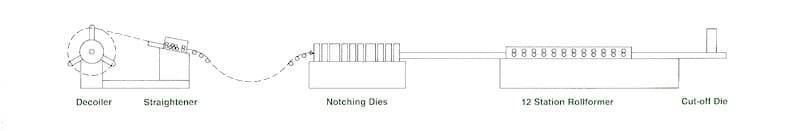

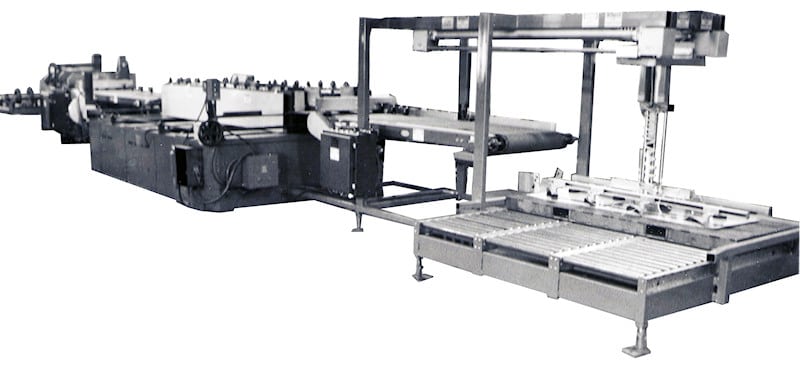

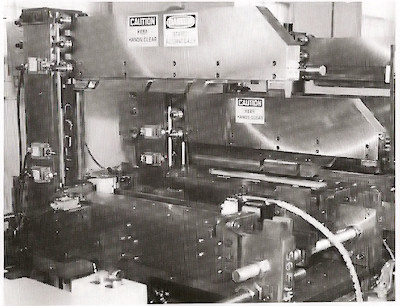

Pre-Painted Cabinets Rollformed and Tangent Bent Into a 3-Sided Furnace Wrapper |

|

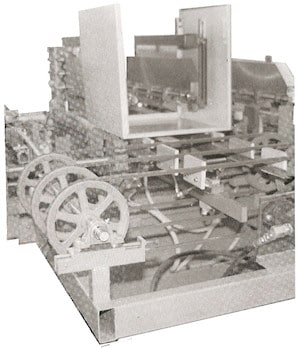

| We offer a complete line of Sheet Stackers and Destack / Feed Systems. This System was designed and built for a major manufacturer of furnace and air conditioning equipment. Starting from pre-punched and notched blanks, we developed an On-Time Production Cell to feed and form the Pre-Painted Cabinet Shells directly onto the Infeed Conveyor. Utilizing a Destack and Feed Rollformer, and four Ram Tangent Endformer, the blanks are fed and formed and staged to operate as a Just In Time Part Call-Up System.The Destacker picks up the entire pre-notched and punched part from the skid and places it onto the Feed Conveyor.

Sheet Fanners, Rotary Vacuum ensure a single part feed into the Rollformer. A part will always be staged on the Feed Conveyor. Upon demand, the Conveyor will feed the blank into the Rollformer and the Destacker will feed another in its place. The Rollformer will form both edges at the same time and is variable for five different widths. The part will be fed out the Rollformer onto another Feed Conveyor and Staging Area. This Conveyor will hold a Rollformed part and feed it directly into the four Ram Endform/Tangent Bender as required. The Endformer will form pre-rollformed panes into final formed Three-Sided Cabinets in five different depths, four widths and two heights. The Outer Rams will form a 90° flange on both ends and the Inner Rams will form the Cabinet into a Three-Sided Wrapper. The parts are threaded directly from the Feed Conveyor, formed then ejected laterally onto the next Conveyor to the assembly area. We build a wide variety of Destack and Stacking Systems, and Endform/Tangent Bend Units. Design and application vary to best suit the customer’s production requirements. |

|