We started Custom Rollform Products, Inc., back in 1981 in St. Louis, MO, with the simple idea that quality and satisfaction sell. It really works! Give your customers quality, dependable equipment at fair prices and they will become your best sales tool and come back again and again.  |

Today’s industries are looking for dedicated, Pre-tooled Systems designed for on time (just in time) production. Systems that utilize the most up to date technology to maximize production and minimize setup, downtime and inventories. |

No matter what your requirements are, simple, retrofit, retool, Free Standing Rollformer or a complete, turnkey System, I’m sure we can fulfill your needs.

The personal attention you deserve

I believe you’ll find we’re large enough to handle your every production requirement, yet small enough to give every customer and job the personal attention to detail they deserve. Our slogan, “Quality Design Means Production You Can Afford,” still holds true. Price does not always determine the best. We maintain a constant effort to achieve the best design, the best technology, the best equipment and the best service. Let us show you our best. It may be the best move you ever made.

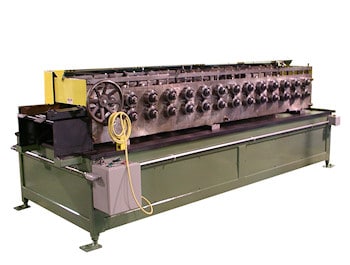

Besides Basic Rollform Systems, we can incorporate Inline Punching, Notching, Slitting, Louvering and Embossing operations along with Marking, Welding, Tangent Wingforming, Endbending, and Assembling.

These are some Basic Systems we can offer either as individual Units or integrated into a Complete Production System.

|

|

|

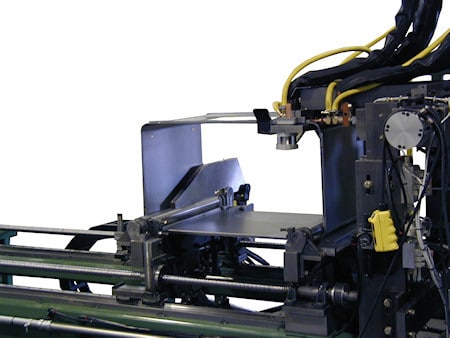

Programmable Tangent Wingformer w/ Inline Welder

Our Rollformers can be pre-tooled to run two to three separate cross sections on the same Spindle Housing, eliminating tool changeovers and setups. We offer both Variable Head and Dual Head (Duplex) Rollformers for a Quick Change Application on Panels and Channel sections.

Variable Width Rollformer

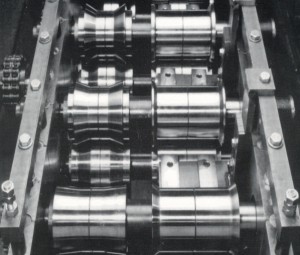

Variable Width Rollform Tooling Setup |

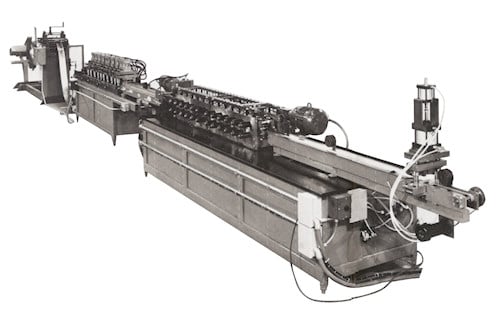

Dual Head (Duplex) RollformerForms edge flanges on 12″ to 60″ wide panels. Can be free standing, blank fed, or inline coil fed. |

Special Material Handling Applications

10 Stage Stack Tower

Retrieves pre-painted pre-cut blanks from ten different skidded stacks onto the Feed Conveyor

|

|

System notches, punches rollform, tangent wingform, and endforms three sided Furnace Wrappers in three different width and length variables.

Note! The System retrieves information directly from the Assembly Line as to the Housing size required. The Notching Rollformer and Tangent Former are programmed to self adjust based on the blank size with no setup or changeover.

|

“I believe you will find we are genuinely interested in and about your production needs and we are unique in our design applications. Our Systems are built with the highest standards in the industry. We use the latest concepts in designing on time production and quick change setup equipment, so you will get the most out of your production time. In addition to our quality designs and workmanship, our prices are also the most competitive in the industry. If you have any questions, please feel free to call. We are looking forward to working with you in the near future.” – Larry Slavik President |