| Tangent Formers Home |

Safes | Electrical Enclosure Boxes & Wireways |

Furnace Wrapper | Air-Conditioning Cabinets | Radius Corners |

3991 Green Park Road * St. Louis, MO 63125 Sales@CustomRollformProducts.com 314-894-3903

- Home

- About Us

- Products

- Automation Systems

- Air Conditioning Cabinets

- Air Make-Up Units

- Blower Housings

- Box Fan Fabrication & Assembly System

- Electrical Enclosure Boxes

- Electrical Wireway

- Fire Damper Frames and Blades

- Furnace Wrapper

- Furnace Wrapper 20 Gauge Pre-Painted CRS

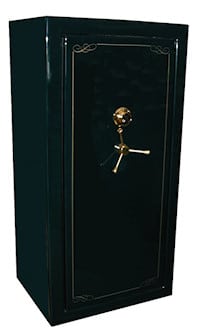

- Gun Safes

- Light Diffuser System

- Oven Cavities

- Personal Safes

- Programmable Coil Feed Slit and Shear Lines

- Shelf Fabrication System

- Stainless Steel Kennel

- Variable Width Rollforming

- Coil Cut to Length Lines

- Coil and Sheet Handling Equipment

- Hydraulic Power Units

- Rollformers

- Stud & Track Systems

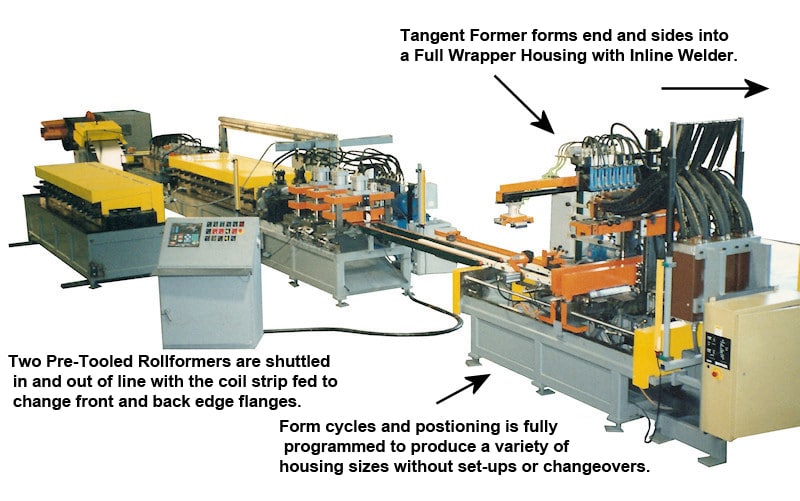

- Tangent Formers, Wingformers & Endformers

- Automation Systems

- Used Equipment

- Rebuild Services

- Brochures

- Video

- Air Conditioning Cabinets

- Air Make-Up Units

- Auto Beading Venturi Housing

- Auto Flue Pipe Dual Flanging System

- Blower Housing Assembly Unit

- Box Fan Fabrication System

- Compact Cut To Length

- Custom Rollform Products

- Electrical Enclosure Boxes

- Electrical Wireway Enclosures

- E Stud & Track Line

- Filter Frame Pre Tooled Two Profiles

- Fire Damper & Blade Lines

- Fluorescent Lens Rollform Frame System

- Full Wrapper Angle Frame Rollformer

- Furnace Cabinet Line

- Furnace Wrapper Cabinet

- Gun Safes

- HD Stud & Track

- Heavy Gauge Coil Cut To Length & Punching System

- Light Diffuser System

- Machine 2

- Oven Cavity

- Personal Safes

- Picture Frame Rollformer

- Programmable Slit & Shear Line

- Roof Curb Fabrication System

- School Bus Rub Rail Rollformer

- Shelf Fabrication

- Stainless Steel Kennel

- Stud & Track

- Tangent Wingformer & Endformer Systems

- Two Stage Form Press System

- Unistrut Channel Production System

- Variable Head Rollformer

- Variable Width Channel Rollformer

- Variable Width Damper Blade Rollformer

- Contact Us

- Financing

- Privacy Policy