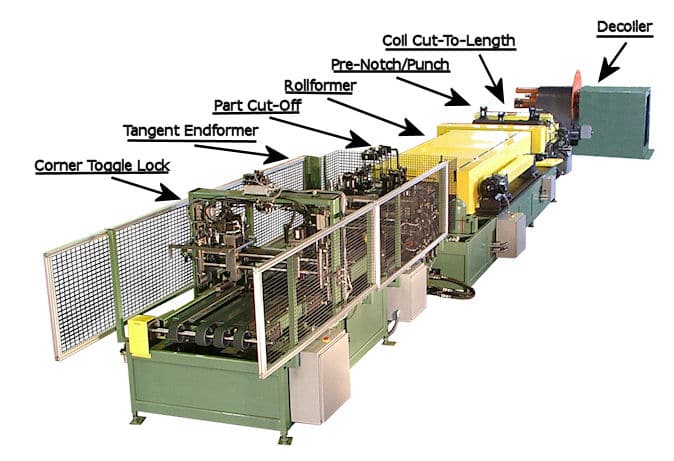

Shelf Fabrication System

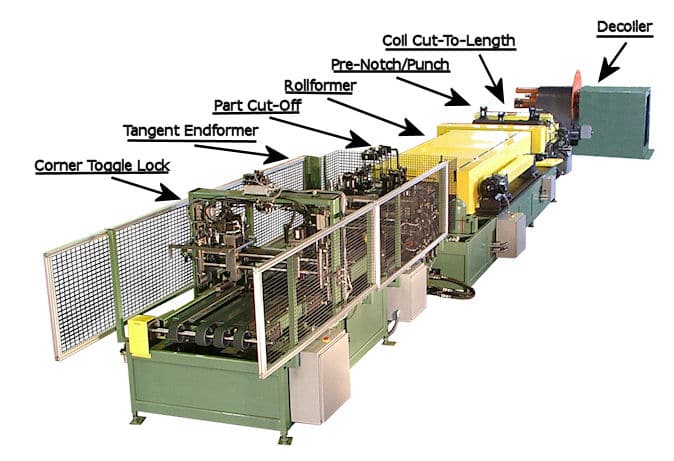

The complete Shelf Fabrication application is actually two Systems in one line.

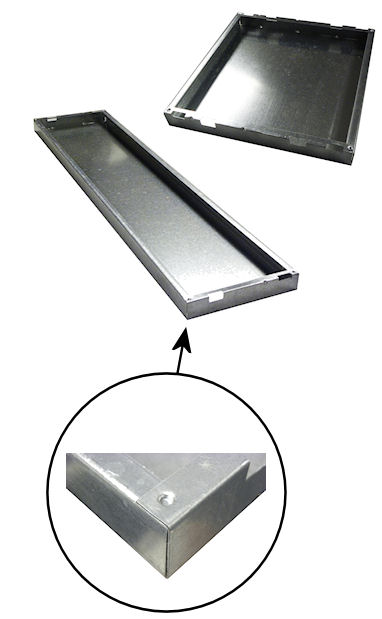

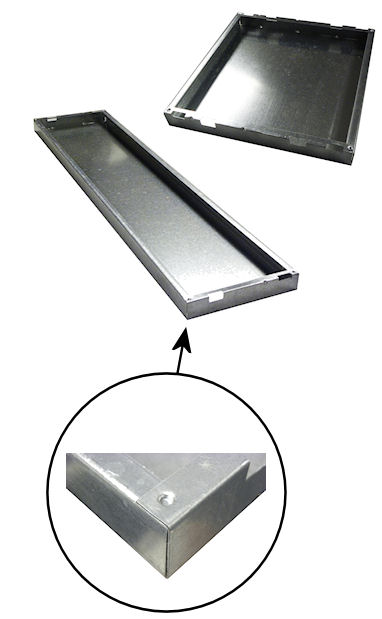

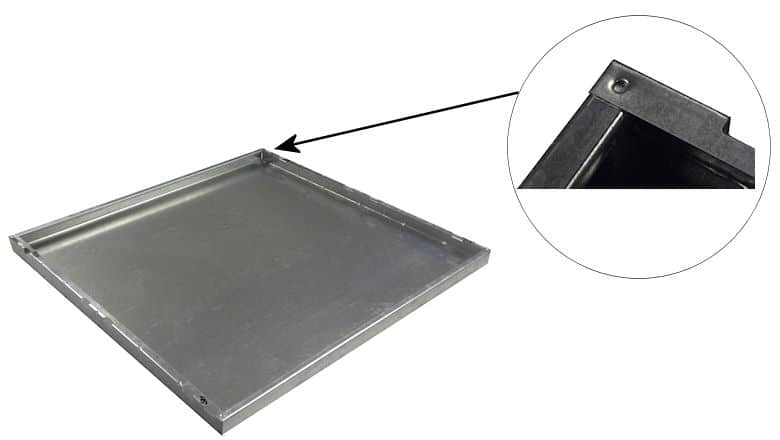

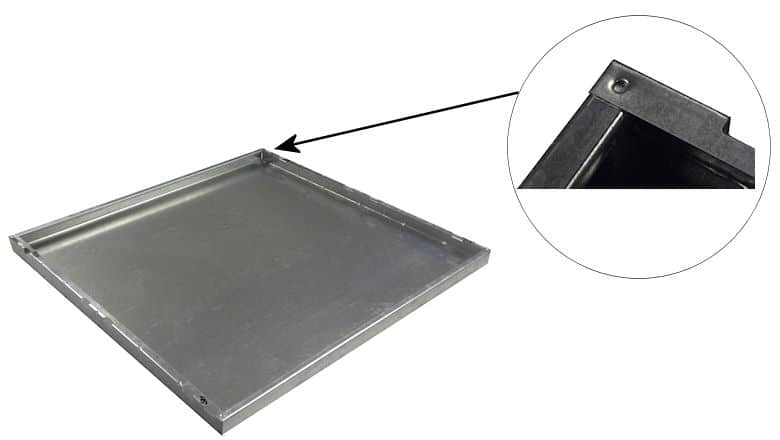

The following application is a complete Coil Feed System. It makes a wide variety of Shelves from 18 gauge galvanized mild steel. The System design is to pre-notch and punch the strip, rollform the two side profiles in a single pass through operation. It then endforms both ends, and toggle lock all four corners in a Fully Automatic Line System.

Full Width Coil Cut To Length Full Width Coil Cut To Length

Blanks sheets from coil between production runs.

The Programmable Microprocess Length Batch Controller will sequence the Feed and cycle the Pre-Notch and Post Cut Off Presses. The rollformed Shelves will then be sequenced through a series of programmed tangent form operations. This forms a double return flange on the lead and trail ends of the Shelves. The Programmable Microprocess Length Batch Controller will sequence the Feed and cycle the Pre-Notch and Post Cut Off Presses. The rollformed Shelves will then be sequenced through a series of programmed tangent form operations. This forms a double return flange on the lead and trail ends of the Shelves.

The Tangent Former Tooling is sectioned and spaced to accommodate the five width variables. This eliminates any setups or changeovers. It is also programmed to sense the overall part length and can accommodate a variety or combination of feed lengths. These can be in a random order without any changeover, down time, or scrap loss.

Inline Corner Toggle Lock System

The Inline Corner Toggle Lock System is designed to toggle or button lock the trail end of one part as it locks the lead end of another. This also allows you to run a variety of feed length combinations eliminating any setup.

Shelving / Blanking Line

The design of this combination Shelving / Blanking Line is another example of how Custom Rollform Products builds special Systems best suited to match the customer’s needs and requirements. We offer a variety of multiple pre-tooled rollform applications to run several profiles or products of the same System. Variations in material thickness and material types can usually be run on the same Rollformer. We work with a variety of special pre-painted, polished, or laminated materials.

Let Custom Rollform Products help you improve your production and increase your bottom line. |

Shelves come in five basic widths from 8” to 30” wide in lengths from 13” to 52” long. Part lengths within the same coil strip width can be run in any quantity or order without additional setups or scrap loss. The Rollformer features our special variable head concept. It varies the Form Rolls and part profile with a Lead Screw / Hand Wheel setting in less than a minute. The Pre-Notch and Punch Press Dies are setup with Lead Screw settings with Micrometer Readouts for a quick change application. All the line settings can change in approximately five to ten minutes to accommodate coil and part width variables.

Two Systems In One Line

The complete application is actually two Systems in one line. Coil Cut To Length and an Automatic Shelf Production Line. It was an estimate that automating the Shelf would eliminate a lot of labor, handling and scrap loss. On the contrary, all their production would require only about 30% of the capacity of the System. We widened the Decoiler, Straightener, and Shear Cutoff on the System. This allows them to also use this as a Blanking Line. The Inline Rollformer is setup on Tracks and can be shuttled in and out of line with the coil strip feed. Transforming the System to a Coil Feed Blanking Line using the same Programmable Feed Controls and Drives takes a matter of minutes.

The new redesigned Shelf has proven to be lighter and stronger by adding darts in the Endformer and toggle locking the corners together.

|

The Programmable Microprocess Length Batch Controller will sequence the Feed and cycle the Pre-Notch and Post Cut Off Presses. The rollformed Shelves will then be sequenced through a series of programmed tangent form operations. This forms a double return flange on the lead and trail ends of the Shelves.

The Programmable Microprocess Length Batch Controller will sequence the Feed and cycle the Pre-Notch and Post Cut Off Presses. The rollformed Shelves will then be sequenced through a series of programmed tangent form operations. This forms a double return flange on the lead and trail ends of the Shelves.