Automation Systems

Boost Your Sheet Metal Production with Custom Rollform Products’ Automation Systems

Custom Rollform Products is not your average rollforming company. We understand the need for efficiency and on-time production in today’s competitive landscape. That is why we offer a complete suite of automation systems designed to streamline your sheet metal fabrication process. Examples are listed below.

From Coil to Finished Product: A Seamless Journey

Custom Rollform Products’ automation systems go beyond just roll forming machines. Our integrated solutions encompass the entire production flow, including:

- Decoiling and Feeding: Efficient decoiler systems ensure smooth material handling from coil to roll former.

- Rollforming: State of the art roll forming machines precisely shape your sheet metal into the desired profile.

- Inline Processing: Integrate punching, notching, slitting, and other operations directly into the line for a continuous workflow.

- Tangent Bending and End Forming: Create complex shapes with precise bends and end forms using their innovative machinery.

- Welding and Assembly: For projects requiring joining multiple parts, Custom Rollform offers integrated welding and assembly solutions.

- Cut to Length Lines: Produce sheared blanks in various lengths with minimal scrap, maximizing material utilization.

Benefits of Automation:

- Increased Efficiency: Automation eliminates manual handling and reduces production time, allowing you to fulfill orders faster.

- Improved Quality: Consistent and precise machine control ensures consistent product quality throughout your runs.

- Reduced Labor Costs: By automating repetitive tasks, you can optimize your workforce and reduce labor costs.

- Enhanced Safety: Automated systems minimize operator interaction with machinery, improving safety on the shop floor.

- Just-in-Time Production: Reduced lead times and lower inventory requirements thanks to efficient material handling.

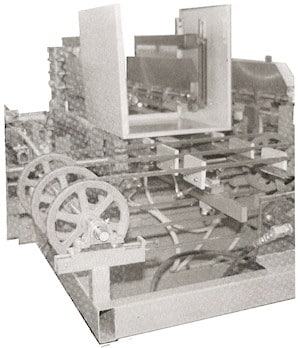

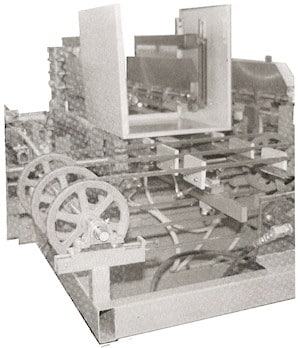

Tangent Forming Air Conditioning Cabinets

(Combination Form Press, Tangent Former & Clinch Lock Unit)

|

|

|

|

Special Patent Pending Tab-Lock Design |

(14 to 16 GA. Galvanized or Pre-Painted)

|

|

The Latest Concepts in On-Time Production Systems

|

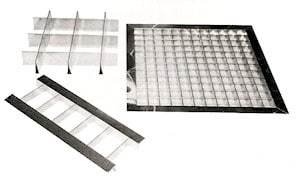

Fire Damper Blades

Fire Damper Frame |

Coil Fed, Rollform Flanges, Programmed

Tangent Former 24” x 24” to 36” x 72”

Full Wrapper (3 Depths)

|

|

Integrated Rollform, Tangent Form, & Welding Application

|

|

Rollformed and Tangent Bent Into 3-Sided Wrappers

|

|

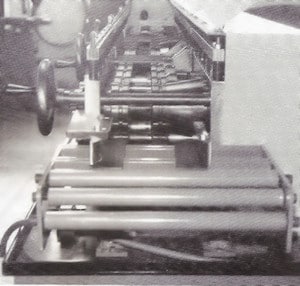

Blank Feed with 8 Position Stack Tower, Pre-Notch & punch, Rollform & Programmable Tangent Wing Form End Form Three Sided Wrapper Cabinet

|

Variety of styles & sizes in minutes |

The most productive Blanking system on the market.

|

|

Full Wrapper Housing 20 GA. Stainless Steel

|

|

(16 Ga. Pre-Painted Steel)

|

|